The cost of energy appears daily in the headlines of the newspapers as there is a huge concern not only because of the impact on the cost of goods but also because of the risk of interruption of Gas’s supply due to the war in Ukraine.

In ManageArt we are the promoters of the Forum for the industrial efficiency or the pharmaceutical sector, and we integrated in the Forum several working groups. In this article want to highlight the common work between the group of purchasing energy and the group of engineering, as it is becoming a key success factor for the management of the crisis.

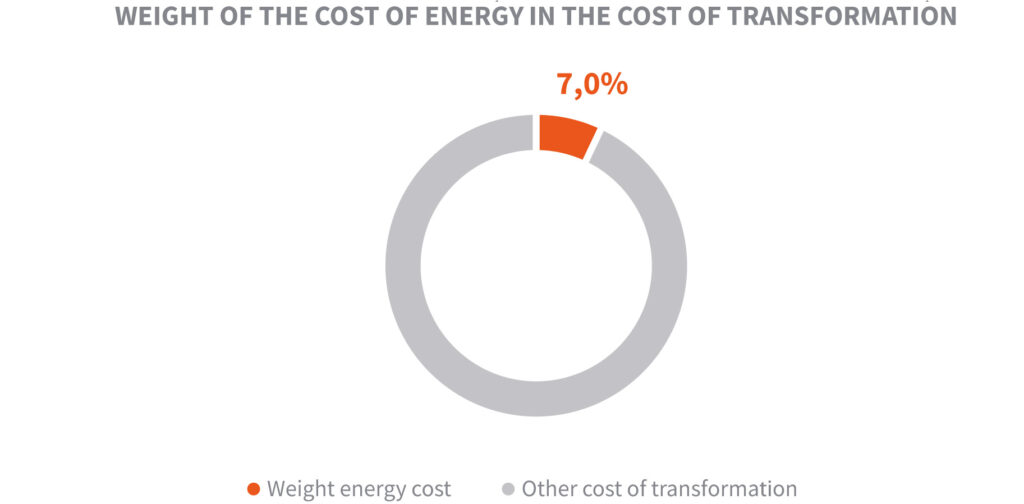

The weight of the cost of energy was 7% in the transformation costs of the sector in 2020

Focusing on the concept of transformation cost, according to ManageArt studies, the weight of the cost of energy until 2020 was around 7% of the total cost of transformation, which may vary depending on the technology and the different types of products.

The transformation cost includes all the costs to transform the raw materials into finished pharmaceutical products, excluding the cost of the raw materials. This indicator is the one that is used to have a real measure of the competitiveness of pharmaceutical production plants because it eliminates from the equation the cost of raw materials and mainly APIs (active principle), whose cost can have great variations between different products.

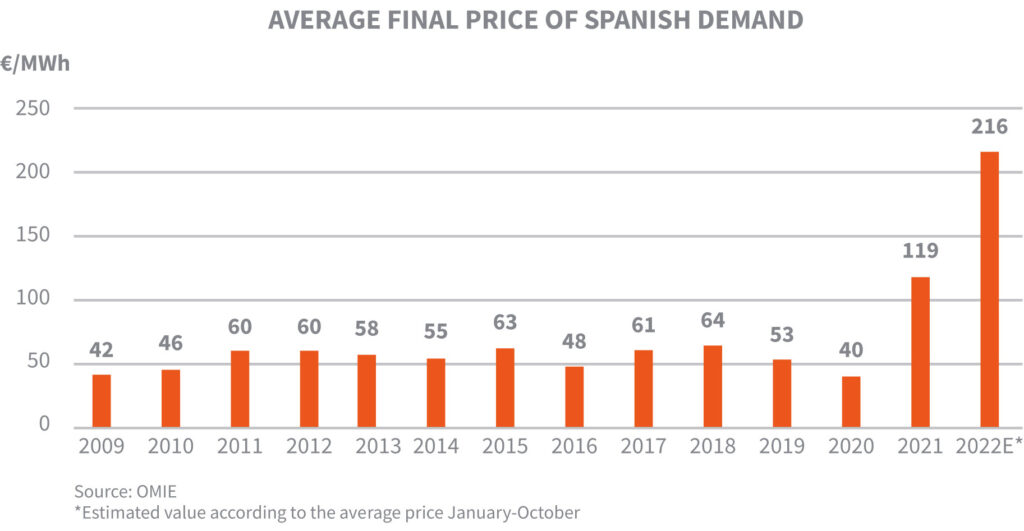

The cost of energy has increased five times since 2020

However, energy costs have been increasing from the second quarter of 2021, recently reaching their maximum levels.

The cost of energy has been affected by this increase according to the purchase management carried out by each company. While the cost of energy of the companies that are part of the ManageArt Forum has been maintained, in other cases the cost of energy has been able to increase five times and the cost of the final bill has tripled despite the actions of the Government to reduce generation tax and VAT.

On top of that, it has been added the threat turned into reality of interruption of the supply of Russian gas to Europe.

The purchasing strategy followed has made it possible to keep energy costs constant

In 2015, within the ManageArt Forum for Industrial Efficiency in the pharmaceutical sector a group for the joint purchase of energy made up of 11 companies was formed. The main objective of the group was to obtain a greater joint purchasing capacity and consequent increase in weight negotiation. With this, the group has been making decisions to purchase energy at the most appropriate moments thanks to having contracts with a minimum of two years, anticipating the ups and downs of the market, and setting positions at propitious moments. The result has been that the members belonging to this group have not suffered an increase in the cost of energy in 2022, thus managing to avoid an increase in costs of more than 20 million euros for the members of the group.

For the year 2023, the group has closed the purchase price of electricity and partially for the case of gas, which has managed to avoid an increase in costs of 17 million euros. Meanwhile, the group continues attentive to the future evolution of the markets to go taking positions for the next years.

The risk of restrictions on gas consumption worries pharmaceutical companies

A big concern of pharmaceutical companies is the risk of lack of gas supply. Although the pharmaceutical sector is considered an essential sector, and thanks to this it would not be affected by unlikely restrictions in the supply of gas, the companies in the sector are doing their homework and are quantifying these risks and evaluating alternatives.

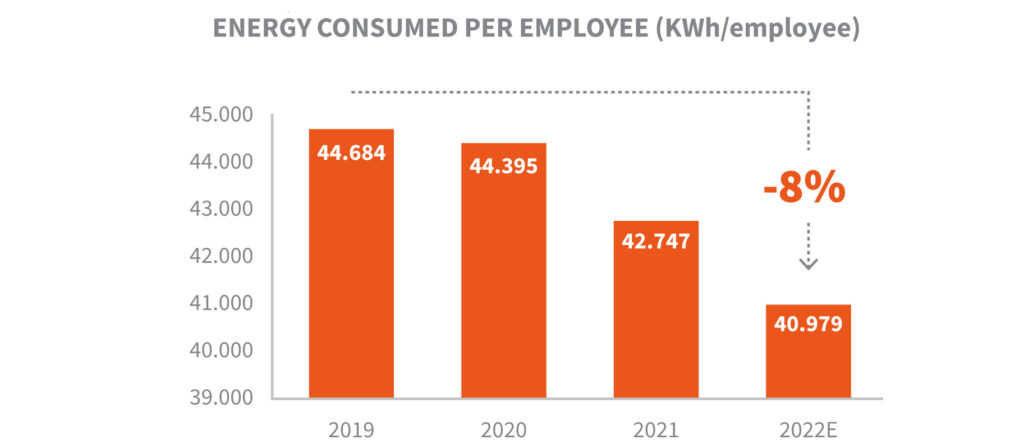

The pharmaceutical sector has been improving its energy efficiency for years and has managed to reduce unit energy consumption by 8%:

However, given the uncertainty of the gas supply the technological alternatives that exist to further reduce energy consumption and to reduce gas consumption have been discussed. The alternatives that have been proposed have been the installation of aerothermal equipment or the use of other alternative fossil fuels to natural gas.

Aerothermal energy is the best technology to reduce energy consumption

This solution is being valued very positively by engineers since it allows for a very notable increase in efficiency. This is since plants in the pharmaceutical sector have the particularity that throughout the year they require the generation of cold and heat or steam at the same time, which allows a very high degree of energy efficiency.

With old low prices the payback of an investment of this type used to be around 5 years, but with the current price level and the particularities of the sector plants the payback of these investments is reduced to little more than one year.

Gas continues to be essential for the operation of production plants

Aerothermal energy is highly efficient and allows gas consumption to be reduced, but it does not eliminate it in the event that steam generation is required. For this reason, companies in the sector have considered the use of other fuels to replace gas in the event of gas consumption restrictions.

However, they have mostly been discarded since they require expensive storage facilities, are not very energy and economically efficient. Only the diesel option allows coexistence with the consumption of natural gas and therefore can be a real alternative to energy restrictions.

Pharmaceutical production plants focus on energy efficiency improvement and planned energy purchase.

As a conclusion to this article, the pharmaceutical sector faces the challenge of continuing in its process of improving the sustainability and efficiency of its processes. the current crisis of energy prices is pushing the sector to accelerate this process by installing more efficient equipment and less dependent on fossil fuels.

On the other hand, the planned purchase of energy constitutes the other fundamental lever to avoid the fluctuations of the markets and facilitates the purchase of energy at predictable and affordable costs in the income statements of the laboratories.