A production plant manager in the pharmaceutical industry is like an orchestra conductor. Their goal is to get the final product out on time, with the right quality and at the right cost.

Among all the day-to-day adversities to achieve this objective, the crisis of the pandemic is added, which has meant a before and after in the way in which the production plants of the pharmaceutical sector are managed, especially the supply chains. In such a challenging industry, competitors are continually working to gain an advantage, and time is of the essence. To anticipate and know how to detect where to put the effort and improve in these areas, using benchmarking is a successful solution.

Benchmarking is a comprehensive comparison tool that analyzes both indicators and the best practices carried out by companies in the same segment as yours. This methodology is used to quantify points of improvement and efficiency at a pharmaceutical plant or API production plant to improve its results.

Discover your starting point to find out just how far you can go.

Benchmarking identifies problems or distortions, it is a photograph that shows us where to put in the effort, in order to implement a potential action plan in our pharmaceutical production plant.

How do we do it? The combination of different indicators, with their segmentation, results in a high number of comparative charts (> 500) with a high level of detail to define action plans with quantifiable results.

It is highly important to compare a plant’s management indicators by creating standard segments, such as:

- Productivity by technology.

- OEEs/Installation efficiency by complexity in terms of formats, batch size, etc.

- Indirect costs by company size.

- Claims by market or product type.

- Cross-check and continuous validation of information.

It is necessary to have continuous support throughout the process, to verify and validate data. The level of detail has to be rigorous and the relevant KPIs are needed to be able to identify points of improvement profoundly.

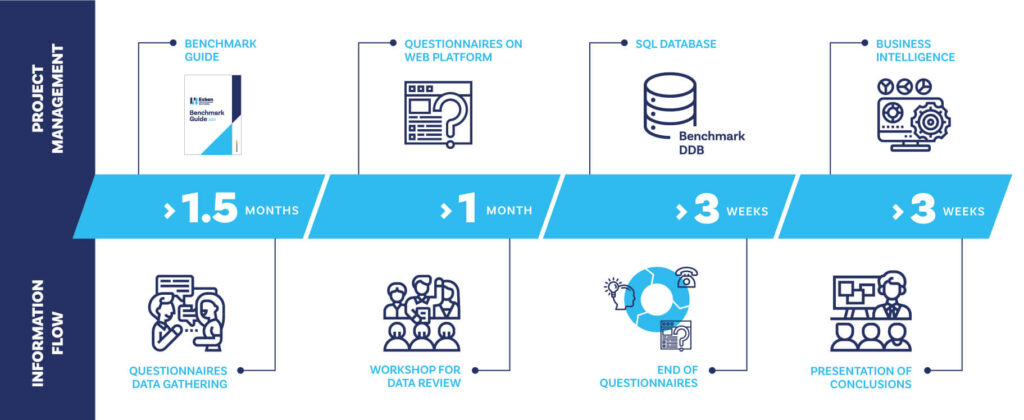

What are the phases of a good benchmarking methodology?

GATHERING OF INFORMATION: We define the benchmark guide and then ee monitor and provide support throughout the process (workshop).

ANALYSIS AND VALIDATION: We analyse and segment based on the plant profile and its specific features. In this phase, continuously validating information is essential.

WE PRESENT CONCLUSIONS: We present a report of results to establish priorities in the areas for improvement.

In this last phase, we present a detailed report containing a plant’s indicators compared to those corresponding to the segment to which the plant in question belongs, helping to establish priorities within these different areas for improvement:

- Transformation cost

- Supply chain efficiency

- Production efficiency

- Quality efficiency and costs

- Efficiency in the Industrial area

Benchmark timeline

How have some pharmaceutical plants grown thanks to benchmarking?

The best example you can find is one of our Case Studies developed by Manageart with its Benchmarking tool Exben.

You can download it here >> https://exben.manageart.es/case-study

If you are interested in getting the main metrics and conclusions of the impact of COVID in pharmaceutical sites, you can download the study here >> https://exben.manageart.es/impact-of-covid-on-pharmaceutical-sites